Table of Contents

Innovative Features of the Euro 5 Gasoline Engine Self-Powered Dynamo Versatile Unmanned Flail Mower

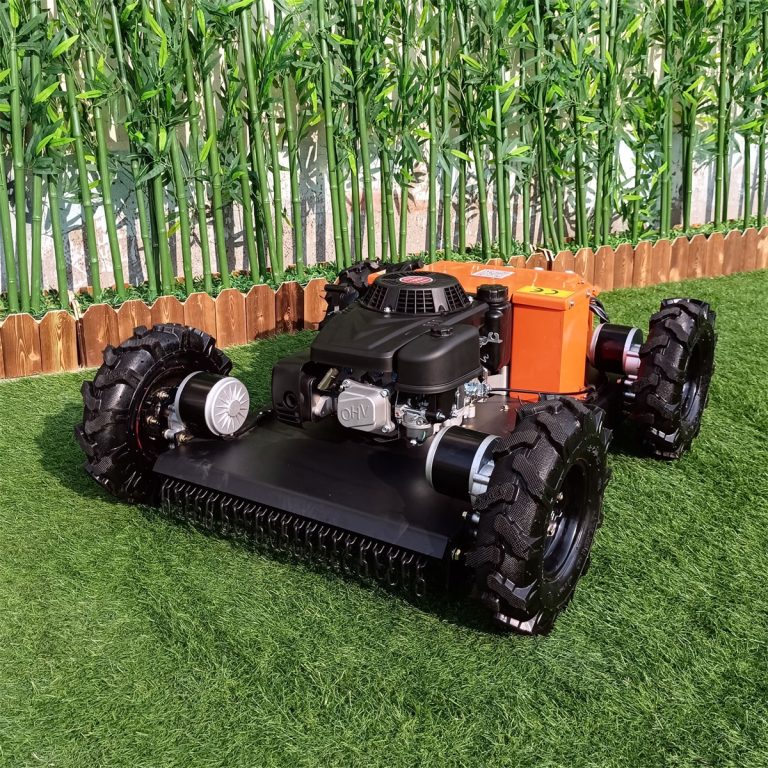

The Euro 5 gasoline engine self-powered dynamo versatile unmanned flail mower is equipped with a robust V-type twin-cylinder gasoline engine. Specifically, it utilizes the Loncin brand’s model LC2V80FD, which boasts an impressive rated power of 18 kW at 3600 rpm. This powerful 764cc engine ensures strong performance, making it ideal for various agricultural and landscaping tasks. Designed for efficiency, the engine features a clutch that engages only upon reaching a predetermined rotation speed. This thoughtful engineering not only optimizes fuel consumption but also enhances the overall performance of the mower, allowing it to tackle challenging terrains with ease. The combination of power and control makes this mower a reliable choice for professionals in the field. Safety is a paramount concern, and the Euro 5 gasoline engine self-powered dynamo versatile unmanned flail mower addresses this with a built-in self-locking function. The machine only moves when both power is activated and throttle is applied, preventing unintended movement. This feature significantly enhances operational safety, ensuring that users can work with confidence even in tricky environments.

Safety is a paramount concern, and the Euro 5 gasoline engine self-powered dynamo versatile unmanned flail mower addresses this with a built-in self-locking function. The machine only moves when both power is activated and throttle is applied, preventing unintended movement. This feature significantly enhances operational safety, ensuring that users can work with confidence even in tricky environments.

Versatility and Performance for Diverse Applications

The innovative design of the Euro 5 gasoline engine self-powered dynamo versatile unmanned flail mower allows for multi-functional use with interchangeable front attachments. Users can easily switch between a 1000mm-wide flail mower, hammer flail, forest mulcher, angle snow plow, or snow brush. This versatility makes it an exceptional tool for heavy-duty grass cutting, shrub and bush clearing, vegetation management, and snow removal.

The innovative design of the Euro 5 gasoline engine self-powered dynamo versatile unmanned flail mower allows for multi-functional use with interchangeable front attachments. Users can easily switch between a 1000mm-wide flail mower, hammer flail, forest mulcher, angle snow plow, or snow brush. This versatility makes it an exceptional tool for heavy-duty grass cutting, shrub and bush clearing, vegetation management, and snow removal.

Furthermore, the intelligent servo controller plays a critical role in the operation of the Euro 5 gasoline engine self-powered dynamo versatile unmanned flail mower. It precisely regulates motor speed and synchronizes the left and right tracks, enabling the mower to travel in a straight line without constant adjustments. This automation reduces the operator’s workload and minimizes the risks associated with overcorrection on steep slopes, promoting safer and more efficient operation.

Furthermore, the intelligent servo controller plays a critical role in the operation of the Euro 5 gasoline engine self-powered dynamo versatile unmanned flail mower. It precisely regulates motor speed and synchronizes the left and right tracks, enabling the mower to travel in a straight line without constant adjustments. This automation reduces the operator’s workload and minimizes the risks associated with overcorrection on steep slopes, promoting safer and more efficient operation.